Embracing the Future: Making Room For Our New 1,000 Ton Press

In the pursuit of excellence, innovation is our guiding star. Today, we are thrilled to announce a significant leap forward for our injection molding capabilities: the installation of our brand new 1,000 ton press. This state-of-the-art addition signifies a monumental shift towards greater energy efficiency and the production of even higher-quality parts. As we bid farewell to the old, we eagerly welcome the new era of precision engineering.

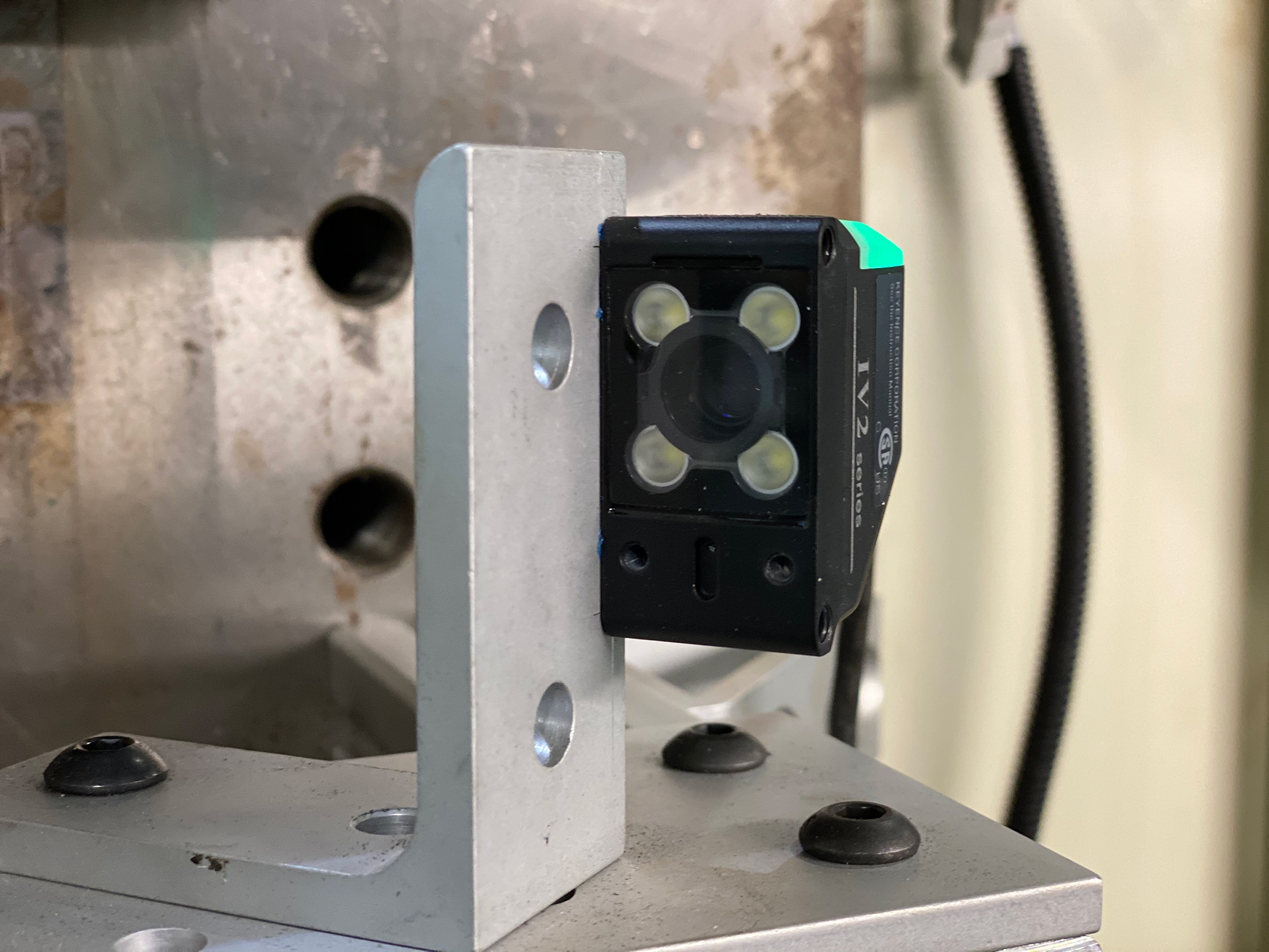

With cutting-edge design and precision engineering, this press consumes significantly less energy per part produced compared to its predecessors. Its advanced control systems and real-time monitoring allow for unparalleled accuracy in forming intricate and complex components. This means parts with tighter tolerances, smoother finishes, and superior overall quality.

The installation of this 1,000 ton press – in addition to the 3 already running, we have opened up new opportunities for our manufacturing capabilities. From larger and more complex components to higher volume production runs, our enhanced capacity empowers us to serve our clients with even greater flexibility and responsiveness. We believe that by embracing the latest advancements in manufacturing technology, we can exceed your expectations and provide you with parts that not only meet but surpass industry standards.

It’s not just a machine; it’s a symbol of our dedication to progress, quality, and sustainability. We invite you to join us in celebrating this milestone and look forward to the products that will emerge from our enhanced manufacturing capabilities. Together, we’re shaping the future of precision engineering.